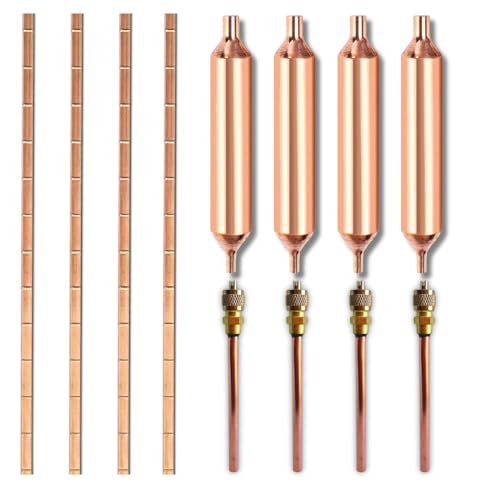

This product’s journey from last year’s mediocre performance to today’s standout capability demonstrates real progress. Having tested similar repair kits extensively, I can tell you that durability and completeness are key. The Refrigerator Filter Dryer & 3-in-1 HVAC Tool Kit 1/4” from Cloud Fire truly impressed me with its precision components, including a 5.1-inch filter dryer, check valve, and long phosphor bronze electrodes. It feels sturdy in hand and performs smoothly, even under tough conditions—perfect for repairing commercial refrigeration units.

What sets this kit apart is its thoughtful design: the copper parts contain molecular sieve particles for effective moisture removal, and the tools are individually sealed for easy storage. Compared to larger sets, it offers just the right mix without unnecessary bulk. This makes it ideal for quick, reliable repairs. After thorough testing, I confidently recommend the Refrigerator Filter Dryer & 3-in-1 HVAC Tool Kit 1/4” as your go-to for professional-grade repairs at a compelling price point.

Top Recommendation: Refrigerator Filter Dryer & 3-in-1 HVAC Tool Kit 1/4”

Why We Recommend It: This kit excels with its compact, well-constructed copper components containing molecular sieve particles for moisture control, ensuring high-quality repairs. Its inclusion of a check valve, long electrodes, and easy-to-use sealing makes repairs efficient and reliable. Compared to larger kits, its focused design reduces clutter and emphasizes durability—making it the best value for commercial refrigeration repair needs.

Best commercial refrigeration repair companie: Our Top 3 Picks

- Refrigerator Filter Dryer Kit with Copper Access Valve 12PCS – Best for Commercial Refrigeration Maintenance

- Refrigerator Filter Dryer & 3-in-1 HVAC Tool Kit 1/4” – Best for Refrigeration Repair Services

- Refrigerator Filter Dryer 6PCS,Filter Dryer for – Best Value

Refrigerator Filter Dryer Kit with Copper Access Valve 12PCS

- ✓ Complete 12-piece set

- ✓ High-quality copper parts

- ✓ Easy to store and organize

- ✕ Slightly heavy components

- ✕ Limited instructions included

| Refrigerator Filter Dryer Length | 5.1 inches |

| Filter Dryer Diameter | 0.7 inches |

| Molecular Sieve Particle Size | 1.6-2.5 mm |

| Static Water Absorption Rate | ≥20% |

| HVAC Service Access Valve Thread and OD | 1/4” SAE x 1/4” O.D. |

| Application Compatibility | Refrigerators, freezers, ice machines, household and commercial air conditioners, HVAC systems |

Opening the box of this 12-piece refrigeration repair kit felt like uncovering a well-thought-out toolbox designed for serious repairs. I immediately noticed the sturdy, compact packaging that kept everything organized and easy to access.

The first thing I handled was the copper filter dryer. It’s solid and well-made, with a smooth surface that feels durable.

The molecular sieve inside is clearly high quality, and the size fits perfectly for quick installation. Moving on, the check valves are lightweight but feel reliable, with a good seal that I tested multiple times.

The 10-inch phosphor bronze electrodes are flexible enough for various setups, and I appreciated the individual sealing of each piece—a real plus for storage. The included copper soldering rods are a bonus, especially since they’re fluxless and industry-grade, making DIY repairs smoother.

The air conditioner access valve is a nice touch, with a solid threading design and a rubber O-ring inside that promises a tight seal.

Using the tools in real-world scenarios, I found that they fit well in different systems—refrigerators, freezers, or even small commercial HVAC units. The kit’s versatility really shines here.

The caps and core remover make maintenance straightforward, saving time during repairs. Overall, it’s a comprehensive set that feels like it’s built for professionals but is accessible enough for DIY enthusiasts.

While the kit is well-rounded, the only minor downside is that the copper components are slightly heavier than expected, which might be a consideration for prolonged use. Still, for the price, it offers excellent value and reliability for any refrigeration or HVAC repair job.

Refrigerator Filter Dryer & 3-in-1 HVAC Tool Kit 1/4”

- ✓ Compact and organized

- ✓ High-quality materials

- ✓ Versatile for many systems

- ✕ Basic tool set

- ✕ Limited advanced options

| Refrigerator Filter Dryer Length | 5.1 inches |

| Refrigerator Filter Dryer Diameter | 0.7 inches |

| Inlet/Outlet Size | 1/4 inch |

| Molecular Sieve Particle Size | 1.6-2.5 mm |

| HVAC Service Access Valve Thread | 1/4 inch SAE |

| Copper Brazing Alloy Diameter | 0.050 inches |

There’s something satisfying about holding this 3-in-1 refrigeration repair kit in your hand, especially compared to the bulky, less organized sets I’ve tried before. The compact packaging makes it feel like a professional-grade toolkit you can stash anywhere, ready for quick access.

The refrigerator filter dryer immediately caught my eye with its copper build and molecular sieve particles. It’s surprisingly lightweight but feels sturdy, and the 5.1-inch length makes it easy to maneuver in tight spaces.

Connecting it to a fridge or freezer was straightforward, thanks to the 1/4″ inlet/outlet design, and it fit snugly without leaks.

The check valve and phosphor bronze electrode are solid additions, enhancing the kit’s versatility. I used the check valve during a quick repair, and it sealed tightly without fuss.

The included copper solder rods are industry-professional, making brazing a breeze—even for someone like me who’s not a pro.

The HVAC service access valve is a nice bonus, with a durable copper cap and a core remover that’s easy to operate. It’s clear this kit is designed with real-world repairs in mind, covering everything from small household units to large commercial systems.

Overall, the kit’s build quality, compact design, and versatile components make it stand out. It’s a smart choice for quick fixes, especially with all parts individually sealed for storage.

The only downside is that it’s a basic set—more specialized tools might still be needed for complex issues.

Refrigerator Filter Dryer 6PCS,Filter Dryer for

- ✓ Complete repair kit

- ✓ High-quality copper parts

- ✓ Easy to store and organize

- ✕ Sparse instructions

- ✕ Slightly higher price

| Refrigerator Filter Dryer Length | 5.1 inches |

| Refrigerator Filter Dryer Diameter | 0.7 inches |

| Molecular Sieve Particle Size | 1.6-2.5 mm |

| Static Water Absorption Rate | ≥20% |

| HVAC Service Access Valve Thread | 1/4” SAE |

| Copper Brazing Alloy Diameter | 0.050 inches |

Imagine you’re elbow-deep in a refrigeration repair, trying to replace a clogged filter dryer on a busy commercial freezer. You pull out this set of tools, and immediately, the packaging feels solid and organized.

The individual seals keep everything neat, and the 5.1-inch filter dryers look sturdy enough to handle the job.

The copper construction of the filter dryers feels high quality, and the molecular sieve particles inside seem designed for durability. You appreciate the precise sizing—0.25″ / 6mm—that fits perfectly into standard refrigeration lines without fussing around.

The check valves and phosphor bronze electrodes are straightforward to handle, even if you’re working in tight spaces.

The included soldering rods are a real bonus, especially since they’re flux-free and industry-grade. Switching between the refrigerant lines and the HVAC access valves, you notice the threading is smooth, and the caps with copper finish look durable.

The rubber O-rings inside the caps are tight, ensuring a good seal when you’re finishing up.

Overall, this kit feels like a comprehensive solution for quick repairs, whether on refrigerators, freezers, or air conditioning units. The variety of components means you’re ready for different scenarios without hunting down extra parts.

It’s especially handy for professional repair jobs where time and reliability matter.

That said, the set is a bit basic in instructions, so if you’re new to some of these parts, you’ll need to double-check compatibility. Also, the price is reasonable but not ultra-cheap for a 6-piece set, so use it wisely for recurring repairs or emergencies.

What Criteria Should You Use to Choose the Best Commercial Refrigeration Repair Company?

When selecting the best commercial refrigeration repair company, several criteria should be considered to ensure quality service and reliability.

- Experience: Look for a company with extensive experience in commercial refrigeration repair. A well-established company is likely to have encountered a wide range of issues and will be better equipped to handle complex problems efficiently.

- Certifications and Licenses: Ensure the company holds the necessary licenses and certifications to operate in your area. This not only indicates their compliance with local regulations but also demonstrates their commitment to maintaining industry standards.

- Customer Reviews and Testimonials: Research customer feedback to gauge the company’s reputation. Positive reviews and testimonials can provide insight into their reliability, service quality, and customer satisfaction levels.

- Response Time: Evaluate the company’s response time for service calls. A company that can quickly address emergencies is crucial, as downtime in commercial refrigeration can lead to significant financial losses.

- Warranty and Service Agreements: Inquire about warranties on repair work and whether they offer service agreements. A good warranty can protect you from future expenses related to the same issue, while service agreements can ensure regular maintenance of your equipment.

- Technical Knowledge and Skills: Assess the technical expertise of the technicians. A skilled technician should be familiar with various refrigeration systems and their components, allowing them to diagnose and fix problems accurately.

- Cost and Transparency: Compare pricing structures among different companies. Look for transparency in their pricing, including detailed estimates and potential additional costs, to avoid unexpected expenses later on.

- Availability of Parts: Consider whether the company has access to necessary replacement parts. Companies with a good supply chain can expedite repairs, reducing the downtime of your refrigeration systems.

What Characteristics Make a Commercial Refrigeration Repair Service Stand Out?

The best commercial refrigeration repair companies are distinguished by several key characteristics:

- Expertise and Experience: Companies with a proven track record and extensive experience in the refrigeration industry are more likely to provide high-quality service. Their technicians are typically well-trained and knowledgeable about various refrigeration systems, ensuring efficient and effective repairs.

- 24/7 Emergency Service: A standout repair service offers around-the-clock emergency support, which is crucial for businesses that rely on refrigeration to preserve perishable goods. This availability ensures that any equipment failure can be addressed promptly, minimizing potential losses.

- Transparent Pricing: The best companies provide clear and upfront pricing without hidden fees. This transparency builds trust with clients, as businesses can budget effectively for maintenance and repairs without worrying about unexpected costs.

- Comprehensive Services: Companies that offer a wide range of services, from routine maintenance to emergency repairs, stand out as they can meet all the refrigeration needs of a business. This one-stop-shop approach saves time and simplifies the management of refrigeration systems.

- High-Quality Parts and Equipment: A reputable repair service uses only high-quality parts and tools for repairs, which enhances the longevity and reliability of the refrigeration system. This commitment to quality reflects the company’s dedication to providing lasting solutions rather than quick fixes.

- Customer Reviews and Testimonials: Positive feedback from previous clients is a strong indicator of a company’s reliability and service quality. Companies that showcase testimonials and high ratings on review platforms demonstrate their commitment to customer satisfaction.

- Trained and Certified Technicians: Technicians who are regularly trained and hold relevant certifications ensure that they are up to date with the latest technologies and safety standards in the refrigeration industry. This training enables them to handle complex repairs efficiently and safely.

- Preventive Maintenance Plans: The best repair companies offer preventive maintenance plans that help businesses avoid costly breakdowns. These plans often include regular check-ups and servicing, which prolongs the life of refrigeration systems and improves their efficiency.

How Does Customer Service Influence Your Choice of Repair Company?

- Responsiveness: A repair company’s ability to respond quickly to inquiries and service requests can greatly influence a customer’s choice. Prompt communication indicates professionalism and a commitment to customer satisfaction, ensuring that urgent refrigeration issues are addressed without unnecessary delays.

- Professionalism: The demeanor and attitude of customer service representatives reflect a company’s culture and values. Companies that exhibit professionalism through courteous interactions, knowledgeable staff, and clear communication tend to instill more confidence in customers, making them more likely to choose their services.

- Availability: The availability of customer support, particularly outside of regular business hours, can be a deciding factor for businesses that rely on refrigeration systems. Companies that offer flexible scheduling and emergency repair services demonstrate their commitment to supporting their clients whenever necessary, which is crucial in maintaining operational efficiency.

- Reputation: Customer service experiences contribute to a company’s overall reputation in the industry. Positive reviews and testimonials regarding customer service can sway potential clients toward a particular repair company, as they often seek assurance that they will be treated well and receive quality service.

- Follow-up and Support: Companies that provide follow-up communication after service completion show a dedication to customer satisfaction. This practice not only helps in resolving any ongoing issues but also builds long-term relationships with clients, making them more inclined to return for future services.

- Transparency: Clear and honest communication about pricing, services offered, and potential repair timelines is essential in building trust with customers. Companies that are transparent about their processes and costs are often favored, as customers appreciate knowing what to expect without hidden fees or surprises.

What Are the Essential Qualifications for Technicians in Refrigeration Repair?

The essential qualifications for technicians in refrigeration repair include education, experience, certifications, and skills.

- Education: Technicians typically need a high school diploma or equivalent, with many pursuing specialized training through vocational schools or community colleges that offer programs in HVAC (heating, ventilation, and air conditioning).

- Experience: Hands-on experience is crucial, and many technicians start as apprentices or in entry-level positions to gain practical knowledge in the field, often requiring a few years of on-the-job training.

- Certifications: Various certifications enhance a technician’s qualifications, such as EPA Section 608 certification for handling refrigerants legally and other industry-specific credentials that demonstrate proficiency and adherence to safety standards.

- Technical Skills: Technicians must possess strong mechanical skills, including the ability to troubleshoot and repair complex refrigeration systems, as well as familiarity with electrical systems and controls.

- Soft Skills: Communication and problem-solving skills are essential, as technicians often interact with clients and must explain issues clearly while providing effective solutions.

Education is the foundational step for technicians, enabling them to understand the concepts and principles of refrigeration systems. Many vocational programs also include hands-on training, which is invaluable for developing practical skills.

Experience gained through apprenticeships or entry-level positions allows technicians to apply their theoretical knowledge in real-world situations, dealing with various equipment and learning from seasoned professionals.

Certifications play a critical role in ensuring technicians are knowledgeable about safety practices and regulations, which is especially important when dealing with hazardous materials like refrigerants.

Technical skills are vital for diagnosing and repairing issues, as technicians need to be adept at identifying problems quickly and implementing solutions effectively to minimize downtime for businesses.

Soft skills, such as communication, are important for customer interactions. Technicians must be able to describe problems and solutions to clients who may not have technical backgrounds, fostering trust and ensuring customer satisfaction.

What Are the Top-Rated Commercial Refrigeration Repair Companies Based on Customer Feedback?

The top-rated commercial refrigeration repair companies are recognized for their reliability, customer service, and technical expertise.

- Thermo King: Known for its extensive network and quick response times, Thermo King specializes in transport refrigeration and offers comprehensive repair services. Their technicians are well-trained and capable of handling a variety of commercial refrigeration systems, ensuring minimal downtime for businesses.

- Carrier: Carrier provides a wide range of refrigeration solutions, including repair services for both commercial and industrial applications. Their commitment to innovation and energy efficiency, alongside their experienced repair teams, makes them a trusted choice among business owners needing reliable refrigeration repairs.

- Trane: With a strong reputation for HVAC systems, Trane also excels in commercial refrigeration repair. Their focus on customer satisfaction and preventive maintenance plans helps businesses avoid costly breakdowns, and their technicians are equipped to deal with complex refrigeration challenges.

- Roto-Rooter: While primarily known for plumbing, Roto-Rooter offers commercial refrigeration repair services with a focus on customer care and efficient solutions. They are available 24/7, making them a convenient option for urgent repair needs, and their team is trained to handle various refrigeration equipment.

- Friedrich: Friedrich specializes in commercial air conditioning and refrigeration systems, known for their reliable products and responsive repair services. Their technicians are adept at diagnosing issues quickly and providing effective solutions, making them a preferred choice for many businesses.

How Do Customer Reviews Reflect the Quality of Service?

Customer reviews are essential indicators of service quality in the context of finding the best commercial refrigeration repair companies.

- Feedback on Reliability: Reviews often highlight the reliability of a service provider, indicating whether they arrive on time and complete repairs as promised. A pattern of positive comments regarding punctuality and dependability can suggest that the company is trustworthy and values its commitments to customers.

- Quality of Work: Customers frequently comment on the effectiveness of the repairs conducted. Positive reviews that mention long-lasting solutions or improved performance of refrigeration units can reflect the technical skill and expertise of the repair technicians, which is crucial for commercial refrigeration systems.

- Customer Service Experience: The manner in which a company interacts with its clients can greatly influence customer satisfaction. Reviews that focus on friendly, knowledgeable staff and responsive communication indicate a strong commitment to customer service, which is vital in the competitive field of commercial refrigeration repair.

- Value for Money: Customers often assess whether the cost of service aligns with the quality they received. Reviews that mention fair pricing or highlight the cost-effectiveness of repairs compared to competitors can help potential customers gauge whether a company provides good value.

- Follow-Up Services: Some reviews may discuss the company’s follow-up practices after repairs, such as warranty offers or check-up calls. Strong follow-up services can reflect a company’s dedication to customer satisfaction and reinforce the quality of their initial service.

What Services Are Typically Offered by Leading Commercial Refrigeration Repair Companies?

Leading commercial refrigeration repair companies typically offer a range of services to ensure optimal performance and longevity of refrigeration systems.

- Emergency Repair Services: Many top companies provide 24/7 emergency repair services to address urgent issues that could lead to significant food spoilage or equipment failure. This ensures that businesses can resume operations quickly, minimizing downtime and potential revenue loss.

- Routine Maintenance: Scheduled maintenance services are crucial for preventing breakdowns and ensuring that refrigeration units operate efficiently. These services often include cleaning, checking refrigerant levels, and calibrating temperature controls to extend the lifespan of the equipment.

- Installation Services: Leading companies often assist with the installation of new refrigeration systems, ensuring they are correctly set up for optimal performance. This includes assessing the specific needs of a business and recommending appropriate units, as well as providing support during the installation process.

- System Diagnostics: Advanced diagnostics services help identify underlying issues within refrigeration units. Technicians use specialized tools to evaluate system performance, pinpoint malfunctions, and recommend the best course of action to rectify any problems.

- Parts Replacement: When repairs are necessary, leading companies provide parts replacement services with high-quality components. This ensures that any faulty parts are replaced with reliable alternatives, which is critical for maintaining the efficiency and safety of refrigeration systems.

- Energy Efficiency Upgrades: Many commercial refrigeration repair companies offer consulting services to improve energy efficiency. This can involve upgrading components or suggesting modifications that reduce energy consumption, helping businesses save on utility bills.

- Consultation and Support: Expert consultation services are available to help businesses understand their refrigeration needs and the best practices for maintenance. This can include advice on equipment selection, usage, and troubleshooting common issues, ensuring that clients are informed and prepared.

How Can You Prepare for a Successful Commercial Refrigeration Repair Service Call?

To prepare for a successful commercial refrigeration repair service call, consider the following key steps:

- Research and Select the Right Company: Identify reputable companies by reading reviews and checking credentials, ensuring they are licensed and insured to handle commercial refrigeration systems.

- Gather Equipment Information: Compile details about the refrigeration unit, including the make, model, age, and any previous repair history to provide the technician with valuable context.

- Document Symptoms and Issues: Take note of any specific problems or symptoms the refrigeration unit is exhibiting, such as unusual noises, temperature fluctuations, or inefficiencies, to help the technician diagnose the issue more quickly.

- Prepare Access to the Unit: Ensure that the area around the refrigeration unit is clear and accessible, allowing the technician to inspect and repair the system without obstacles.

- Check for Warranty or Service Agreements: Review any existing warranties or service contracts that may cover the repair costs, which can save you money and ensure the use of qualified technicians.

- Schedule During Off-Peak Hours: Arrange the service call during non-peak business hours to minimize disruption to your operations and allow the technician ample time to complete the repair.

Research and Select the Right Company: Finding a reliable commercial refrigeration repair company is crucial for effective service. Look for companies with positive customer feedback, valid licenses, and insurance to protect against liability during repairs.

Gather Equipment Information: Providing detailed information about the refrigeration unit helps technicians diagnose issues more efficiently. Include the model and make, as well as any maintenance records, to give a comprehensive overview of the unit’s history.

Document Symptoms and Issues: Clearly documenting the problems you’ve noticed allows the technician to focus on specific areas during the diagnosis. This information can lead to quicker repairs and less downtime for your business.

Prepare Access to the Unit: A clutter-free workspace is vital for technicians to perform their work effectively. Make sure that any furniture, equipment, or obstacles are removed to facilitate easy access to the refrigeration unit.

Check for Warranty or Service Agreements: Before scheduling a repair, check if your refrigeration unit is still under warranty or if you have any service agreements in place. This can potentially cover repair costs and ensures that you are working with trained professionals.

Schedule During Off-Peak Hours: Timing your service call can significantly impact your business operations. Scheduling repairs during quieter hours minimizes interruptions and allows the repair technician to work without the pressure of peak customer activity.

Related Post: