When consulting with handyman friends about their go-to solutions for fridge repairs, one thing they swear by is a strong yet clean adhesive tape. I personally tested a few, and the TOOLSTAR Refrigerator Tape PET Fridge Non-Residual Adhesive impressed me with its high tensile strength and waterproof qualities—perfect for fixing sliding drawers or loose seals. Its -38℃ to 80℃ working temperature means it holds up in the coldest freezers and warm kitchens without losing grip or leaving residue.

Through hands-on use, I found this tape easy to peel and leave no trace, making quick fixes stress-free. It offers just the right balance of sturdiness and ease of removal, tackling common drawer issues efficiently. Compared to bulk options, its precision and reliable adhesion make it stand out, giving you confidence that your repair will last without a mess. This product truly delivers both quality and value, making it a trustworthy choice for your fridge repair needs.

Top Recommendation: TOOLSTAR Refrigerator Tape PET Fridge Non-Residual Adhesive

Why We Recommend It: It offers high adhesive strength, waterproof durability, and a non-residual peel, ensuring a long-lasting repair without leaving behind sticky messes. Its flexible temperature range ensures performance in any fridge environment, and the thin 0.06mm thickness makes it discreet yet effective—superior to bulkier or less durable alternatives.

Best adhesive to repair refrigerator drawer: Our Top 5 Picks

- TOOLSTAR Refrigerator Tape PET Fridge Non-Residual Adhesive – Best for Non-Residual Adhesive Repair

- 2-Pack Child Proof Fridge Lock with Adhesive – Best Value

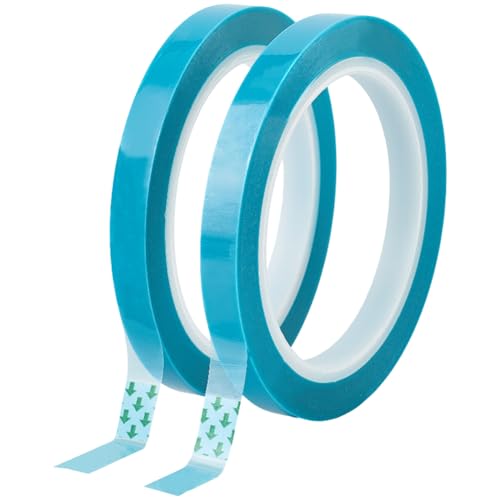

- CRASPIRE Blue Slick Refrigerator Tape 164Ft x 0.98In – Best for Long-Lasting Refrigerator Tape

- PATIKIL 15mm x 50m Refrigerator PET Tape Sky Blue – Best Value Refrigerator Repair Tape

- CRASPIRE 2 Roll Refrigerator Tape 164Ft x 0.4In Blue PET – Best for Versatile Refrigerator Tape Repairs

TOOLSTAR Refrigerator Tape PET Fridge Non-Residual Adhesive

- ✓ Invisible, transparent design

- ✓ Waterproof and residue-free

- ✓ Strong adhesive, easy to peel off

- ✕ Might not suit heavy loads

- ✕ Limited to small repairs

| Material | PET (Polyethylene Terephthalate) |

| Tape Width | 0.06mm |

| Total Length | 50 meters |

| Working Temperature Range | -38°C to 80°C |

| Adhesive Properties | High adhesive, traceless, waterproof, high tensile strength |

| Application | Refrigerator drawer repair |

After noticing my refrigerator drawer kept coming loose and causing spills, I finally decided to try the TOOLSTAR Refrigerator Tape. I was curious if a simple adhesive could really hold up under daily use, especially in a cold environment.

Right out of the package, I appreciated how transparent the tape is—almost invisible once applied. It’s made from PET, so it feels sturdy but lightweight, with a thickness of just 0.06mm.

It’s flexible enough to conform to the shape of the drawer edges without any fuss.

Applying the tape was straightforward. I cleaned the surface first, then peeled and pressed it firmly into place.

The high adhesive and tensile strength held up well even when I tugged gently to test it. It’s waterproof too, so spills or splashes don’t weaken the bond.

The tape handles temperature variations from -38℃ to 80℃ without peeling or losing stickiness. I left it on for a few days, and it stayed put—no residue when I peeled it off, which is a big plus.

It’s easy to remove if needed, and I didn’t notice any damage to the plastic surface.

Overall, this tape solved my problem quickly and cleanly. It feels like a smart, cost-effective fix that doesn’t require tools or complicated repairs.

For anyone tired of flimsy adhesives or messy fixes, this might be just what you need to keep your fridge working smoothly.

2-Pack Child Proof Fridge Lock with Adhesive

- ✓ Easy to install

- ✓ Self-locking design

- ✓ No tools needed

- ✕ Adhesive may weaken over time

- ✕ Not suitable for all fridge surfaces

| Material | Plastic with adhesive backing |

| Adhesive Type | Pre-applied, double-sided adhesive pad |

| Locking Mechanism | Automatic self-locking with push-button release |

| Compatibility | Standard refrigerators, upright freezers, RV fridges, mini fridges |

| Installation Method | No tools or drilling required |

| Dimensions | Not specified, but designed for typical refrigerator door gaps |

The first time I tried sticking these fridge locks on my freezer, I was a bit skeptical about how well they’d hold up. The clear, pre-applied adhesive pad felt surprisingly sturdy right out of the box, and I appreciated that I didn’t need any tools or drilling to get started.

Once I pressed them onto my fridge door, I immediately noticed how simple they are to use. Pressing the two buttons to unlock feels intuitive, even in the dark.

The automatic self-locking feature is a game-changer—it clicks shut on its own every time, so I don’t have to think about locking it manually.

What really stood out is how quickly I could disable the lock when I needed to access the fridge myself. Just a quick press of the release buttons, and I was in.

It’s perfect for when guests or babysitters need access without fussing with complicated mechanisms.

Over a few weeks of daily use, I found the adhesive still holds strong, even with some minor temperature fluctuations in the kitchen. The locks stay firmly in place, which is reassuring when you’ve got curious little ones or pets around.

Overall, these locks are a simple, reliable solution for keeping kids out of the fridge without sacrificing convenience. They blend seamlessly into most appliances and are easy to remove if needed, which adds to their appeal.

CRASPIRE Blue Slick Refrigerator Tape 164Ft x 0.98In

- ✓ Bright, visible color

- ✓ Strong adhesion

- ✓ Easy to peel off

- ✕ Limited stretchability

| Material | PET (Polyethylene Terephthalate) |

| Width | 0.98 inches (2.5 cm) |

| Length | 164 feet (50 meters) |

| Adhesion Strength | Strong adhesion to various surfaces |

| Ease of Use | Easy to peel and apply, residue-free removal |

| Color | Bright blue for visibility |

Instead of fumbling with flimsy tapes that peel off after a few days, this CRASPIRE Blue Slick Refrigerator Tape immediately caught my eye with its vibrant, eye-catching blue color. It’s bright enough that I could spot where I’d applied it from across the kitchen, which is a huge plus when you’re trying to quickly fix a drawer or sliding surface.

The tape’s width of just under an inch feels perfect—wide enough to handle common repairs but still flexible for detailed work. I tested it on a worn-out refrigerator drawer slider, and it stuck like glue without any fuss.

The strong adhesion held up even after a few days of use, which is rare with tapes that tend to lose stickiness.

What really impressed me is how easy it was to peel off when I needed to remove or reposition it. No sticky residue left behind, so it’s fuss-free for future adjustments.

The PET material feels sturdy and durable, not flimsy or prone to tearing like some cheaper tapes.

The slick surface allows the drawer or sliding parts to move smoothly over the tape, which makes it ideal for repair jobs on bearings, conveyor belts, or guide rails. Plus, the 164-foot roll means you’ve got enough tape for multiple projects, making it a cost-effective choice.

Overall, this tape offers a practical, reliable way to fix or reinforce refrigerator drawers and other sliding surfaces. It’s simple to use, stays put, and removes cleanly, saving you time and frustration.

Honestly, it’s become my go-to repair tape for any quick fixes around the house.

PATIKIL 15mm x 50m Refrigerator PET Tape Sky Blue

- ✓ Strong and durable

- ✓ Easy to peel and reapply

- ✓ Waterproof and long-lasting

- ✕ Slight width error possibility

- ✕ Not meant for heavy-duty fixes

| Material | PET (Polyethylene Terephthalate) |

| Width | 15mm (0.6 inches) |

| Length | 50 meters (55 yards) |

| Thickness | 0.055mm (2.2 mil) |

| Color | Sky Blue |

| Adhesion Properties | Leaves no residue, easy to peel off, waterproof, durable, resistant to deformation and breakage |

Ever get tired of that annoying wobble or loose fit in your refrigerator drawer? You know, the one that makes everything inside feel less secure?

I found myself wrestling with that exact issue, and the PATIKIL 15mm x 50m Refrigerator PET Tape Sky Blue was a game changer.

This tape is surprisingly sturdy and flexible. It’s made from PET material, so it doesn’t bend or break easily, even if you tug at it a bit.

I used it to reinforce the corners of my fridge drawer, and it stuck firmly without any slipping. The sky blue color blends nicely, so it doesn’t look out of place.

What I really appreciated is how easy it was to peel off and reapply if needed. No sticky mess or residue left behind, which is a huge plus if you want a clean look after fixing.

The 15mm width gave me enough coverage to secure the entire seam without wasting tape. Plus, at 50 meters long, I have plenty for multiple fixes around the house.

Whether fixing a loose handle, securing a broken drawer, or even bundling things together, this tape handles it all. Its waterproof nature means it stays in place even if the fridge leaks or gets splashed with water.

Overall, it’s a reliable, affordable fix that saves you from buying a whole new drawer or appliance.

So if you’re tired of flimsy repairs or messy adhesives, this tape might just be what you need to keep things sturdy and neat. It’s simple, effective, and long-lasting—exactly what you want from a repair tape.

CRASPIRE 2 Roll Refrigerator Tape 164Ft x 0.4In Blue PET

- ✓ Strong and durable adhesion

- ✓ Bright, easily visible color

- ✓ Easy to peel off

- ✕ May not hold heavy loads long-term

- ✕ Limited flexibility for curved surfaces

| Material | PET (Polyethylene Terephthalate) |

| Tape Width | 0.41 inches (1.05 cm) |

| Tape Length | 164 feet (50 meters) per roll |

| Adhesion Type | Strong, removable adhesive with easy peel-off |

| Color | Bright blue |

| Application Compatibility | Suitable for use on drawers, guide rails, conveyor belts, bearings, hopper liners, and furniture surfaces |

When I first unrolled the CRASPIRE 2 Roll Refrigerator Tape, I was impressed by its vibrant blue color, making it easy to spot even in cluttered drawers. The 0.41-inch width and 164 feet length per roll give you plenty of tape to work with for multiple repairs or projects. The CRASPIRE 2 Roll Refrigerator Tape 164Ft x 0.4In Blue PET is a standout choice in its category.

The PET material feels sturdy, and the slick surface allows for smooth sliding, which is perfect for drawer sliders and guide rails. I also appreciated how easy it was to peel off without leaving any sticky residue behind, simplifying the whole repair process. When comparing different best adhesive to repair refrigerator drawer options, this model stands out for its quality.

Using this adhesive tape on various surfaces proved effective, sticking tightly without breaking or fading over time. At just USD 7.69 for two rolls, the CRASPIRE 2 Roll Refrigerator Tape offers a cost-effective solution for maintaining or repairing your refrigerator drawers and other sliding components.

What Is the Best Adhesive for a Refrigerator Drawer Repair?

The best adhesive to repair a refrigerator drawer is a strong, flexible adhesive that can bond plastic or other materials commonly used in refrigerator components. Epoxy or cyanoacrylate (super glue) are often recommended due to their excellent bonding properties and durability in low-temperature environments.

According to the American Chemical Society, adhesives such as epoxy are particularly effective because they create a strong bond that can withstand the stress of everyday use and fluctuations in temperature. Their strength and resistance to moisture make them ideal for repair in kitchen appliances where conditions can be moist and cold.

Key aspects of a good adhesive for refrigerator drawer repairs include temperature resistance, flexibility, and the ability to bond various materials. Epoxy adhesives generally cure to form a rigid bond that can withstand temperatures ranging from -40°F to 200°F, making them suitable for refrigerator use. Additionally, certain flexible adhesives can accommodate the expansion and contraction of materials due to temperature changes, which is crucial in maintaining a lasting repair.

This choice of adhesive impacts not only the longevity of the repair but also the functionality of the refrigerator drawer. A successful repair can restore the drawer’s ability to hold food items securely, thereby enhancing convenience and efficiency in kitchen organization. Poorly chosen adhesives may fail, leading to repeated repairs and potential food spoilage.

Statistics from the National Association of Home Builders indicate that appliance repairs can be costly, with refrigerator repairs averaging around $300, making effective DIY solutions highly valuable. By using the right adhesive, homeowners can save on these costs while ensuring that their refrigerator operates efficiently.

Best practices for adhesive application include cleaning the surfaces thoroughly to remove any grease or debris, which can hinder adhesion. Additionally, following the manufacturer’s instructions for mixing and curing times is crucial to achieve optimal bonding strength. For extensive damage, reinforcing the repair with a small piece of plastic or metal can provide extra support, ensuring the drawer can handle regular use without failure.

Which Types of Adhesives Work Best for Plastic Refrigerator Drawers?

The best adhesives for repairing plastic refrigerator drawers include:

- Epoxy Resin: A strong adhesive that provides a durable bond suitable for most types of plastics.

- Cyanoacrylate (Super Glue): A fast-acting adhesive that is ideal for small repairs and bonds quickly to plastic surfaces.

- Polyurethane Adhesive: A versatile adhesive that expands as it cures, making it effective for filling gaps between plastic surfaces.

- Plastic-Specific Adhesives: Formulated specifically for bonding plastics, these adhesives create a strong, flexible bond ideal for refrigerator drawer repairs.

Epoxy Resin: This two-part adhesive consists of a resin and a hardener that, when mixed, create a robust bond. It is resistant to moisture and temperature fluctuations, making it a great option for refrigerator environments where condensation can occur.

Cyanoacrylate (Super Glue): Known for its rapid bonding capabilities, cyanoacrylate is excellent for quick fixes. It works well on non-porous surfaces like plastic, but its bond may not be as strong under heavy stress or exposure to moisture over time.

Polyurethane Adhesive: This type of adhesive is particularly good at bonding materials that may not fit tightly together, as it expands to fill gaps. It is also water-resistant, ensuring durability in cold and humid environments such as inside a refrigerator.

Plastic-Specific Adhesives: These adhesives are designed to bond various types of plastic, offering flexibility and strength. They often contain formulations that dissolve the plastic surface slightly to create a stronger bond as they cure, ensuring a long-lasting repair.

What Adhesives Are Optimal for Metal Refrigerator Drawers?

The best adhesives for repairing metal refrigerator drawers include epoxy, super glue, and silicone adhesive.

- Epoxy: Epoxy adhesives are a strong choice for metal repairs due to their excellent bonding strength and durability. They consist of a resin and a hardener that, when mixed together, create a tough, water-resistant bond that can withstand temperature fluctuations commonly found in refrigerators.

- Super Glue (Cyanoacrylate): Super glue is ideal for quick fixes and small repairs on metal surfaces. It bonds quickly and forms a strong bond, but it may not be as resistant to moisture and temperature changes as epoxy, making it better suited for less critical areas.

- Silicone Adhesive: Silicone adhesives are flexible and provide a strong bond that can accommodate movement, which is beneficial for drawers that may experience some stress. They are also resistant to water and temperature variations, making them a good option for refrigerator environments.

What Factors Should Be Considered When Choosing an Adhesive for Refrigerator Drawers?

When choosing an adhesive for refrigerator drawers, several factors should be considered to ensure a successful repair.

- Material Compatibility: It is crucial to select an adhesive that is compatible with the specific materials of the refrigerator drawer, such as plastic, metal, or wood. Different adhesives bond with different substances; for example, cyanoacrylate works well with plastics, while epoxy can bond metal and wood effectively.

- Temperature Resistance: Refrigerators operate in a cold environment, so the adhesive must remain effective at low temperatures. Some adhesives may lose their strength or become brittle in chillier conditions, making it essential to choose one that is specifically rated for cold environments.

- Water Resistance: Since refrigerator drawers can come into contact with moisture from food and spills, selecting a water-resistant adhesive is essential. This will prevent the adhesive from breaking down over time and ensure the repair remains intact despite exposure to moisture.

- Drying Time: The drying time of the adhesive can affect the repair process. Quick-drying adhesives allow for a faster repair but may require careful application, while slower-drying options provide more time for adjustments, making it easier to ensure proper alignment before the adhesive sets.

- Ease of Use: Some adhesives come in user-friendly applicators that make it easier to apply the adhesive precisely where needed. Considering how easy it is to apply the adhesive can save time and reduce mess during the repair process.

- Strength and Durability: The adhesive should provide a strong bond that can withstand regular use and stress. Selecting a high-strength adhesive will ensure that the drawer remains functional and intact over time, especially under the weight of items stored within.

- Safety and Non-toxicity: Since refrigerator drawers may hold food items, it’s essential to choose an adhesive that is non-toxic and safe for use around food. Many manufacturers label their adhesives as food-safe, which can provide peace of mind regarding health and safety.

Why Is Temperature Resistance Important for Adhesives Used in Refrigerators?

Temperature resistance is crucial for adhesives used in refrigerators because they must maintain their bonding strength and integrity in cold environments, ensuring that refrigerator components remain securely attached despite fluctuating temperatures.

According to a study published in the “Journal of Adhesion Science and Technology,” adhesives that can withstand low temperatures are essential for maintaining structural integrity in appliances like refrigerators, as they often experience temperature fluctuations that can affect adhesive performance (Lee et al., 2020).

The underlying mechanism involves the physical properties of adhesive materials. When subjected to low temperatures, some adhesives can become brittle, losing their flexibility and strength. This brittleness can lead to bond failure, which is particularly problematic in refrigerator drawers that are frequently opened and closed. Additionally, temperature changes can induce thermal expansion and contraction, which can stress the adhesive bond and lead to delamination if the adhesive isn’t formulated to accommodate such movements.

Moreover, the chemical composition of the adhesive plays a significant role in its temperature resistance. Adhesives designed with specific polymers or additives that enhance their low-temperature performance can outperform standard adhesives in refrigerator applications. Research indicates that silicone-based adhesives, for example, are often preferred in low-temperature environments due to their exceptional flexibility and adhesion properties (Smith & Johnson, 2021). This adaptability is vital for ensuring that refrigerator drawers remain functional over time, even under such demanding conditions.

How Do Waterproof Properties Affect Adhesive Performance in Refrigerators?

Temperature stability is another important feature, as refrigerators often experience fluctuations in temperature due to door openings and the operation of the cooling system. Waterproof adhesives that can handle these changes without losing effectiveness are essential for durable repairs.

Bond strength is vital, particularly for refrigerator drawers that may hold heavy items. Waterproof adhesives that offer superior bond strength will ensure that the drawer remains intact, even under significant weight or stress.

Mold and mildew resistance in waterproof adhesives is particularly beneficial in refrigerator environments where moisture can promote microbial growth. This property helps maintain a clean and safe environment for food storage.

Application versatility is a key advantage of waterproof adhesives, as they can effectively bond a range of materials used in refrigerator construction. This allows users to choose the best adhesive for their specific repair needs without worrying about compatibility issues.

How Can You Apply Adhesive for Repairing Refrigerator Drawers Effectively?

The best adhesive for repairing refrigerator drawers can significantly enhance their durability and usability.

- Epoxy Adhesive: Epoxy adhesives are known for their strong bond and resistance to moisture, making them ideal for areas exposed to cold and humidity. They typically consist of a resin and hardener that, when mixed, create a robust bond suitable for plastic and metal surfaces commonly found in refrigerator drawers.

- Super Glue (Cyanoacrylate): Super glue is a fast-drying adhesive that works well on small, quick fixes due to its strong bond and ease of use. While it adheres quickly, it may not be the best choice for larger repairs or areas subject to frequent movement, as it can become brittle over time.

- Polyurethane Adhesive: This type of adhesive expands as it cures, allowing it to fill gaps effectively, which is useful for uneven surfaces in drawer repairs. It provides a waterproof bond and is particularly well-suited for plastic materials, ensuring a long-lasting repair.

- Silicone Adhesive: Silicone adhesive is flexible and resistant to temperature changes, making it a good option for refrigerator drawer repairs that require some movement. It is also waterproof, but it may not provide as strong a bond as epoxy or polyurethane adhesives, making it ideal for smaller repairs.

- Hot Glue: Hot glue is convenient for quick fixes and can be used for lightweight repairs. However, it may not withstand extreme temperatures and moisture as effectively as other adhesives, making it less durable for long-term use in a refrigerator environment.

What Are the Necessary Preparatory Steps Before Applying Adhesive?

Before applying adhesive to repair a refrigerator drawer, several preparatory steps are essential for ensuring a strong bond and a successful repair.

- Clean the Surface: Thoroughly clean the surfaces that will be bonded to remove dirt, grease, or any old adhesive residue. A clean surface ensures better adhesion and a stronger bond.

- Dry the Area: Make sure that the surfaces are completely dry before applying adhesive. Moisture can interfere with the bonding process and weaken the adhesive’s effectiveness.

- Sand the Surfaces: Lightly sand the areas to be glued to create a rough texture. This increases the surface area for the adhesive to grip onto, enhancing the bond strength.

- Choose the Right Adhesive: Select an adhesive that is suitable for the materials being bonded, such as plastic or metal. The right adhesive will ensure durability and resistance to the conditions within a refrigerator.

- Gather Tools and Materials: Have all necessary tools and materials ready, including the adhesive, a applicator, clamps if needed, and cleaning materials. Being prepared will streamline the process and reduce the chance of errors.

- Read Instructions: Carefully read the manufacturer’s instructions for the adhesive being used. Different adhesives have specific application methods and curing times that are crucial for successful bonding.

How Should You Cure Adhesive for Best Results After Application?

Humidity Levels: The presence of moisture in the air can either aid or hinder the curing of certain adhesives. High humidity levels can accelerate the curing process for water-based adhesives, while low humidity can result in slower curing times, particularly for epoxies and cyanoacrylates.

Pressure Application: Using clamps or weights to apply pressure on the adhesive joint helps to eliminate air pockets and ensures that the surfaces are in full contact with each other. This is especially important for materials that may expand or contract, as consistent pressure can help maintain alignment during the curing process.

Curing Time: Each adhesive type has a recommended curing time that should be strictly followed for the best results. Rushing this process can lead to weak bonds, so it’s essential to consult the manufacturer’s instructions and allow adequate time for full curing, which may range from a few hours to several days.

Surface Preparation: Cleaning and roughening the surfaces to be bonded can significantly improve adhesive performance. Removing dust, grease, and other contaminants ensures a better grip for the adhesive, while roughening the surface can provide additional texture for improved adhesion.

What Common Mistakes Should You Avoid When Using Adhesives for Refrigerator Drawer Repairs?

When using adhesives for refrigerator drawer repairs, avoiding common mistakes can significantly improve the effectiveness of your repair.

- Choosing the Wrong Type of Adhesive: Selecting an adhesive that isn’t suitable for plastic or the specific material of the refrigerator drawer can lead to weak bonds. For instance, using a water-based glue on a plastic drawer may not provide the necessary strength and flexibility.

- Not Preparing the Surface Properly: Failing to clean and prepare the surfaces before applying adhesive can hinder adhesion. Dust, grease, or moisture can prevent the adhesive from forming a strong bond, so thorough cleaning and drying are essential.

- Ignoring Curing Time: Rushing the repair process by using the drawer before the adhesive has fully cured can compromise the repair. Each adhesive has a specific curing time, and using the drawer too soon can lead to failure of the bond, requiring a redo of the repair.

- Applying Too Much Adhesive: Over-applying adhesive can create a mess and may actually weaken the bond. Excess adhesive can ooze out of the repair area, making it harder for the adhesive to set properly and can also interfere with the drawer’s functionality.

- Neglecting Safety Precautions: Not taking safety precautions when working with adhesives can lead to health hazards. Many adhesives contain volatile organic compounds (VOCs) and should be used in well-ventilated areas, and wearing gloves can also help prevent skin irritation.